Deburring & Finishing

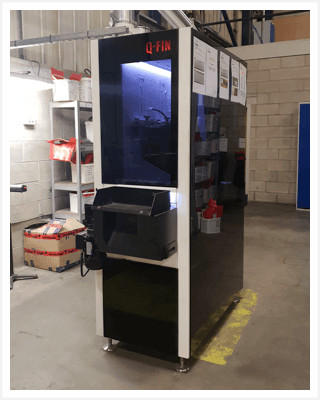

At ANTON, we have recently installed a new grinding and dust control system in our warehouse. The system comprises of 2 new Q-Fin grinding machines and a 30-m long duct system for extracting metal dust, especially from titanium alloys, directly out of the warehouse environment.

The first smaller Q-Fin machine is used for grinding any article that has a maximum dimension of 200 mm in one direction. The machine makes use of multiple rotating brushes and a sand belt of desired grit size to automatically deburr any rough edges and dress material surfaces. The automation allows much quicker dressing operation i.e. between 20-70 articles per minute depending on size, and higher quality surface finish.

The second larger Q-Fin machine has an ability to accommodate larger articles of any thickness and size up to 700mm x 1000mm. This semi-automatic machine allows more freedom of movement and human intervention when deburring larger, thicker or randomly shaped articles without compromising operation efficiency.